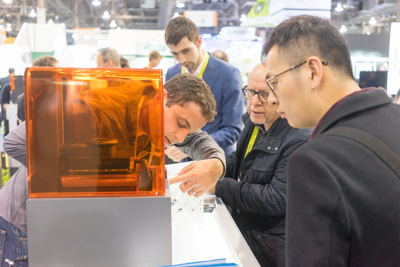

One of my favorite funding stories of all time is how Formlabs' co-founders, Natan Linder and Maxim Lobovsky secured an investment from Mitch Kapor, the founder of Lotus Development Corp. It all started with a tweet from Kapor as he overheard Linder and Lobovsky pitching a VC over dinner... to landing a meeting with Kapor and getting stuck in an elevator... read the full story here.

Since then, the company has raised over $50M in funding including a $35M Series B round of funding last August. Their latest product, the Form 2 brings professional-quality desktop 3D printing to the masses.

We connected with Jory Block, who is part of the People Operations team at Formlabs in Somerville to get the inside scoop on the company's engineering team.

Formlabs is hiring! Check out its BIZZpage.

Keith Cline: How has Formlabs revolutionized the 3D printing industry?

Jory Block: In order to understand how Formlabs has revolutionized the 3D printing industry, you really have to go back to 2011 and survey the landscape. The 3D printing craze was in full swing and the market became flooded with low-cost FDM machines. These consumer-level printers were great for small projects and hobbyists. But there really weren’t any options available for small businesses, entrepreneurs and professionals who needed high resolution, low-cost manufacturing in-house. Formlabs was the first company to bring an SLA 3D printer to people’s desktops and allow them to prototype real-world products without shelling out tens of thousands of dollars. This was a massive game changer for medical researchers, jewelers, film makers and so many other professions who were suddenly able to produce things in-house that were never before possible due to cost and quality. Starting off as an MIT afterschool project, we’ve swelled over the past few years to a now 200+ person company. I think it’s safe to say that we struck a cord in the market!

KC: How do you view Formlabs' culture and what qualities do you look for in potential candidates to join your team? What are the team’s core values?

JB: Culture is extremely important at Formlabs and in the early days (when there were only 10 of us) everyone was naturally very close. We were a pirate crew of friends, out solving interesting and challenging problems. As Formlabs became larger, we knew we wanted to try and preserve the small-company culture that made our team like a family. With now over 200 people combined in our Boston and Berlin offices, the goal is to “keep Formlabs weird,” which is really just a fun way of saying, “let’s keep things interesting.” Since we are trailblazing the way for a new era of low-cost manufacturing, keeping things interesting isn’t difficult. Most of the things we work on have never existed before, which opens the doorway for individuals to contribute their own new ideas to the future of Formlabs.

Potential candidates at Formlabs have to be autonomous problem solvers who are extremely self-motivated and not afraid to take risks. You are given a lot of freedom here and we like curious people who can push themselves without being told what to do and how to do it constantly.

KC: Formlabs is developing an affordable high-resolution 3D printer to enable designers, engineers and makers to easily realize their dreams in beautiful physical form. What are some of the interesting projects the engineering team is tackling?

JB: Everything we produce is an ongoing project and a big focus for us here has always been to improve upon our existing products relentlessly. We release regular updates to our software, printer and materials. We even just released a new line of engineering resins to expand the possibilities of what users are able to make.

Ongoing R&D is also a top priority and I’m aware that’s very vague. But you’ll just have to keep an eye on our blog to see all the exciting things we have planned for 2017!

KC: How does the engineering team stay involved in the Boston tech community?

JB: Formlabs regularly attends meetups and we’ve just started hosting technical talks at our Boston HQ every Thursday. We also travel to technology trade shows all over the world and strive to stay in touch with young engineers through our involvement with programs such as BU Artemis and the Women in Technology Program at MIT, just to name a few.

KC: What has your union with Pinshape earlier this year done for the future of Formlabs?

JB: Our union with Pinshape has allowed Formlabs to give our community a place to share and collaborate. The Pinshape site is a playground of creativity where newcomers and professionals alike can go to meet like-minded individuals and be inspired to make something amazing. We’re very excited that Pinshape has joined Formlabs and we can’t wait to see how the site grows this year.

KC: How does your engineering team keep up with your rapidly-growing user base?

JB: Well first off, we are hiring like crazy. The Form 2 has been extremely popular and so we are sprinting to expand our team to accommodate our growing user base. We have an incredibly talented community of customers and we take their feedback very seriously. Feedback from the community has a huge impact on how we continue to improve and expand our materials library (e.g. our new engineering resins) and which features we end up adding to our Preform software. Our engineers also frequent our online forum and work closely with our customer team to make sure we have a pulse on what’s going on.

KC: What types of activities do members of your team take part in outside the office?

KC: What types of activities do members of your team take part in outside the office?

JB: One thing I really love about Formlabs is that everyone here is extremely active. We regularly have people organizing everything from whiskey tastings to ice climbing in some of the nearby mountain ranges. The interest-diversity here is vast and people are quick to jump in and learn something new. Just to name a few of my favorite internal “clubs” and groups, we have Booklabs, Filmlabs, Whiskeylabs, ping pong tournaments, Fitness Bootcamp, yoga, Ragnar, summer camps, hackathons, karaoke nights, soup groups, hikes and so many other things. If there’s something you are interested in doing outside the office, there’s a pretty good chance you’ll find a bunch of people here willing to do it with you.

Quick story, when I joined Formlabs about 4 years ago, I really wanted to put together a Tough Mudder team...but wasn’t really sure if it was something people here would be interested in doing. Fast forward to today and it’s not only become an annual tradition...but even Max (our CEO) joined up for the 2015 race. It was a ton of fun.

KC: Complete this sentence for our audience: "I love working at Formlabs because…"

|

Adrian Tanner, Optical Systems Engineer "I get to build things that build things and I get to do it with a fantastic group of people." |

|

|

Larissa Little, Materials Engineer “I am always using and deepening my technical expertise to create new resins, while still having the flexibility to work on interdisciplinary challenges with teams from all over the company.” |

|

JJ Hernandez, Materials Engineer “I get to make a difference. If I see a new project we should be pursuing or a new way to create a material, people are open and willing to help me make these company and industry impacting changes happen.” |

|

|

Caitlin Reyda, Mechanical Engineer “I get to design products that are novel and technically challenging with a team of people who really care about the whole user experience. Also, almost all of our mechanical engineers have a Form 2 at their desk. Prototyping our future products using our current product feels like cheating.” |

|

Craig Broady, Mechanical Engineer “I get to play an active role in pushing the boundaries of 3D printing with a cross disciplinary team of smart, dedicated and interesting peers. Also, resin is free, beer is free and there’s a video game arcade.” |

|

|

Meagan Fitzpatrick, Sales Enablement "Even though we’re so much bigger than when I started, everyone I work with feels like one of my closest friends. More importantly, I now have some of the smartest and brightest close friends out of anyone that I know." |

Keith Cline is the Founder of VentureFizz. Follow him on Twitter: @kcline6.